#HappyBirthday #DrMartinLutherKingJr.

#ThankYou for your humble service to humanity

#Peace #NobelPeacePrize #BaptistMinister #AtlantaGeorgia #HumanRights #Segregation #FreedomRiders #RosaParks #LetFreedomRing

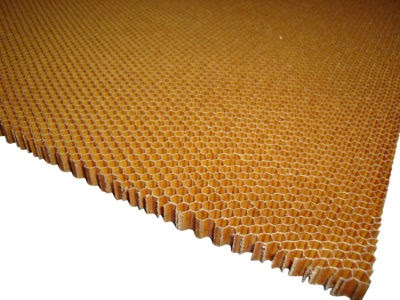

#HoneyCombCorePanels, #HoneycombStructure, #CompositePanels, #CompositeMaterials, #PanelBuilding, #AluminumCompositePanel, #Nomex, #Aramid, #CarbonFiber, #StructuralPanels, #BuildingMaterials, #Construction, #OEM, #Machinery, #Manufacturing, #Automation, #EngineeringServices, #DesignAndBuild, #SheeterStacker, #DipSystems, #Aerospace, #Aircraft #Aviation, #SpaceX #Rockets, #Marine #Maritime